EMAL is a joint venture between Dubai Aluminium Company Limited (DUBAL) and Mubadala Development Company (Mubadala), which was established to construct the world's largest, single site aluminium smelter at Al Taweelah, Abu Dhabi. It produces 1.4 million tonnes of aluminium annually and is the world’s largest single site smelter.

Colt won the tender to provide natural ventilators for the potrooms, baking furnaces and cast houses. The Labyrinth was chosen due to the fact that it has a high coefficient of performance, resulting in a very high ventilation capacity for any given ventilation surface area.

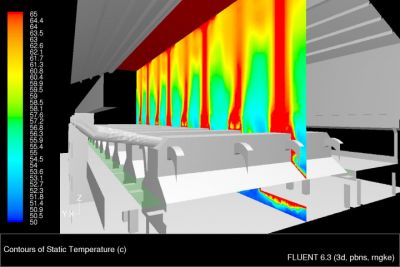

The smelter consists of 4 potrooms, each approximately 1,250 m long. The cast house and anode baking furnace buildings also have non-controllable Labyrinth roof ventilators.

The Labyrinths meet all requirements with regards to wind load, sand load and water resistance. They ventilate continuously without the possibility of rain getting into the building. For this specific smelter, the Labyrinth is being constructed to marine quality standards, due to the proximity of the smelter to the sea.

The Colt Labyrinths were uniquely installed using a purpose-built 'roof car'. Workers drove the vehicle over the opening of the roof, making it the safest method of installation compared to conventional methods. Other advantages of this included reduced time required for installation and minimal disruption to other work within the building.

EMAL benefits from maximum ventilation and the best price / quality / performance ratio while achieving a low temperature on the operating floor, thus achieving better working conditions for its employees.

In 2009 Colt received the distinction of receiving from Emal its Environment, Health and Safety Performance Certificate for being the best contractor on the site with regards to health and safety.